Gallery Of Homes: Carter

Leathered coffee granite tops by Superior Granite.

Free floating chimney range hood over 42" dual fuel range.

Built in DR buffet and china cabinet.

Guest BR.

Guest bath with private access to the lanai.

Up stairs game room with magnificent view of the bay.

We used stainless steel wire rope railing to create an unobstructed view of the bay.

Upstairs game room bathroom.

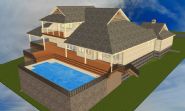

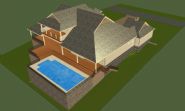

Composite decking, paver pool deck.

Ivy was planted to improve the appearance of the pool containment vessel.

Metal workmen from the Renaissance Man install the architectural railing around the deck.

Gerry assembles the front porch tapered columns. We used marine plywood to ensure durability.

Robert installs stone veneer on the front porch column bases

Gerry opereates the door fan to test the thermal envelope by creating a 50 pascal vacuum inside the building and recording the airflow.

Gerry uses a smoke generator to test for air leakage around the sliding glass door.

Sean seals the joints in the master shower to create a water tight substrate for the walk-in tile shower.

Wrapping the rear porch columns with cement fiber siding.

Leveling the base material that the pavers set on.

Setting the pool pavers.

Zachary installs shake cement siding on the gable ends

Zachary nails off a frieze board on the gable end. Frieze boards give depth to the cornice and make the shake siding stand out.

Steven primes the cut ends of the siding. This is an important and often overlooked step when properly installing cement siding. If you don't seal the cut ends, moisture will absorb into the siding and cause paint blistering.

The upper porch deck has been coated with a pink sealoflex water proof coating. A finish textured wear coating will be applied later. Oh, the coon? Jasper found coon poops in the house and finally tracked down the perp. He ran up the stairs, out the door, and onto the 2nd floor deck but was smart enough not to jump.

Gerry tried to coax him into the trap with sardines and cookies. He's not buying it right now but later on he did go in and we got him.

We are a green builder so in keeping with our commitment to energy efficiency and conservation of natural resources we released him into a nice habitat in the Gulf Breeze area with natural spring feed ponds and plenty of food sources.

The underside of the second floor decking has been sprayed with foam for sound deadening. We also sprayed the drain pipes from the bathroom on the second floor to cut down on the noise in the den below.

Ricky installs screws in the window frames every 8". These windows aren't going anywhere.

Robert applies zip tape window flashing. The window flanges have been caulked, screwed, and zip taped to form a water tight double seal.

Jasper installs copper deck flashing after sealing the sliding glass door sill with a fabric impregnated rubberized coating to protect the vulnerable areas. Note the recess area in the floor which will allow the sliding glass door threshold to set down lower and flush with the tile floor covering.

Red assembles a dutch gable truss set on the ground.

Eddie controls the tag line while Filiberto, Steve, and Ronnie set the pre assembled dutch gable truss set on the garage.

David, Ronnie, Robert, Eddie, and Red counterbalance a rotating pre assembled hip set as it lifts off.

Steve catches a flying hip set.

Filiberto installs a common truss on the garage.

Robert holds the zip wall sheathing in place while Ronnie and Steve nail it off. The zip wall has a green weather proof coating. The mid wall horizontal blocking allows the sheathing to be structurally attached to the framing on all 4 ends with an engineered nailing pattern which creates a solid structural wall panel from top to bottom.

Ronnie and Robert nail off the zip wall while Dustin applies the zip tape which seals the joints between sheathing panels. This system creates an extremely air tight and weather proof thermal envelope which is far superior to the typical uncoated wall sheathing with house wrap common to most new construction in this area. The zip wall coating will actually seal around the nails fastening the sheathing to the wall studs as well as the nails fastening the siding to the walls thus preserving the air tight integrity of the walls. Typical house wrap is full of holes by the time the siding is installed and is highly compromised as an air infiltration barrier. Just about useless in fact. This home is built high on the bluffs overlooking Escambia bay and will be subject to constant breezes and high winds. These air tight walls will ensure low utility bills and a comfortable home regardless of the weather.

Gulf Coast Pools workmen pour the pool wall footings inside the pool containment structure.

Red screws down the floor decking. We're using engineered I-joists for the floor framing. These I- joists are quite a bit stronger and straighter than 2x12's. This floor system will be flatter, stiffer, and more uniform than a conventionally framed floor system using dimensional lumber. The Laminated Veneer Lumber beams support the load bearing walls above.

Dustin applies glue to the I-joists. The plywood floor decking is being glued and screwed to add strength and prevent future floor squeaks. Steve, in the background, is checking lateral alignment of the floor joists while Dale pins them in place with a nail through the decking. Red will follow and screw off the decking.

Jasper grinds the top course of foundation block smooth for an even fit of the floor system.

Willie pours a basement slab in the foundation crawl space. The white coating on the block walls seals the walls from moisture intrusion so that the crawl space can maintain a lower humidity level.

Pat sprays termite treatment on the soil underneath the concrete slab areas.

Jasper and Willie install the welded wire mesh slab reinforcement over the vapor barrier.

Willie and Darin screed the concrete to a level state.

Willie fills in a low spot with a pinch of concrete. I wish my eyes were that good.

Willie bull floats the slab to push the aggregate down below the surface. Good thing the garage isn't one foot deeper.

Willie creates a turned down area in front of the garage in order to keep water from blowing up under the garage door seal.

Darin trowels the garage slab smooth.

Willie sprinkles water on the slab as he operates the rotary trowel to finish the garage concrete surface.

Matt built an 8 foot tall dirt ramp to get his excavator high enough to fill the pool containment structure.

Matt dumps fill into the pool containment structure while Willie operates a mini bobcat to put the fill where it needs to go. The black pipes in the corners are connected to french drains in the bottom to allow any trapped water to escape.

Van and Kevin compact the fill with vibrating blade tampers.

Mike makes a test hole to insert the density measuring probe to see how well the fill dirt has been compacted.

Mike reads the meeter which tests the density of the compacted fill dirt.

Jasper applies the first of 2 coats of masonry sealer to the inside of the pool containment structure to prevent any moisture from seeping through the block walls that might drain down through the paver deck around the pool above.

Willie G pours concrete into the walls of the pool containment structure while Darin finishes it. The boom pump operator is manuevering the boom to keep the nozzle right where Willie needs it.

Willie walks the wall with the pump hose while the boom operator controls the boom. He's using a small diameter hose to better control the flow of concrete. A more liquid concrete mix with smaller gravel and chemical curing retarders is being used for this application.

Willie operates a vibrator which helps the concrete consolidate down into the block cells. We drilled inspection ports at the base of the walls so that we could verify that concrete had flowed all the way to the bottom.

Willie Gaines cuts a grove in the block so horizontal steel rebar can be laid in that course. There will be horizontal steel rebars every 4 courses of block (32").

Jasper drills inspection holes in the bottom of the block walls so we can make sure that concrete fills each cell completely.

Clarence cuts block for the masons with a gas powered saw with a diamond blade.

A 3 wheeled tractor called a spider is used to deliver a cube of block close to where it will be needed.

Falstaff and Eddie B lay up decorative 12" face block on the pool containment structure. Man, those things are heavy!

We used a 118' boom pump to pour the footings. You can see how the footings step down the slope in 8" increments.

Guiermo and Julio measure the layout strings. The strings are attached to wooden structures called batter boards which define a level plane suspended in space at the floor level. Man, those are some tall batter boards in the back!

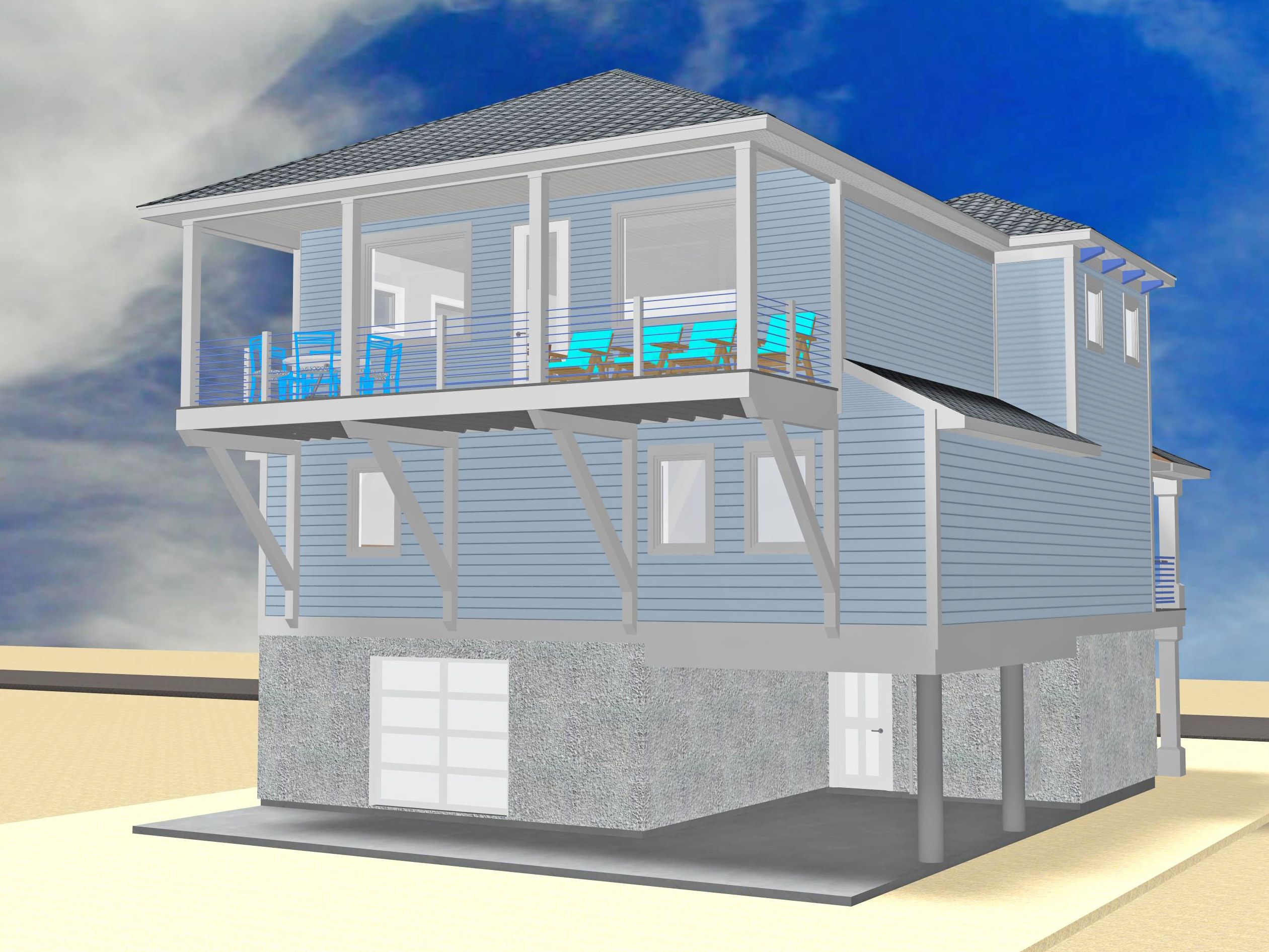

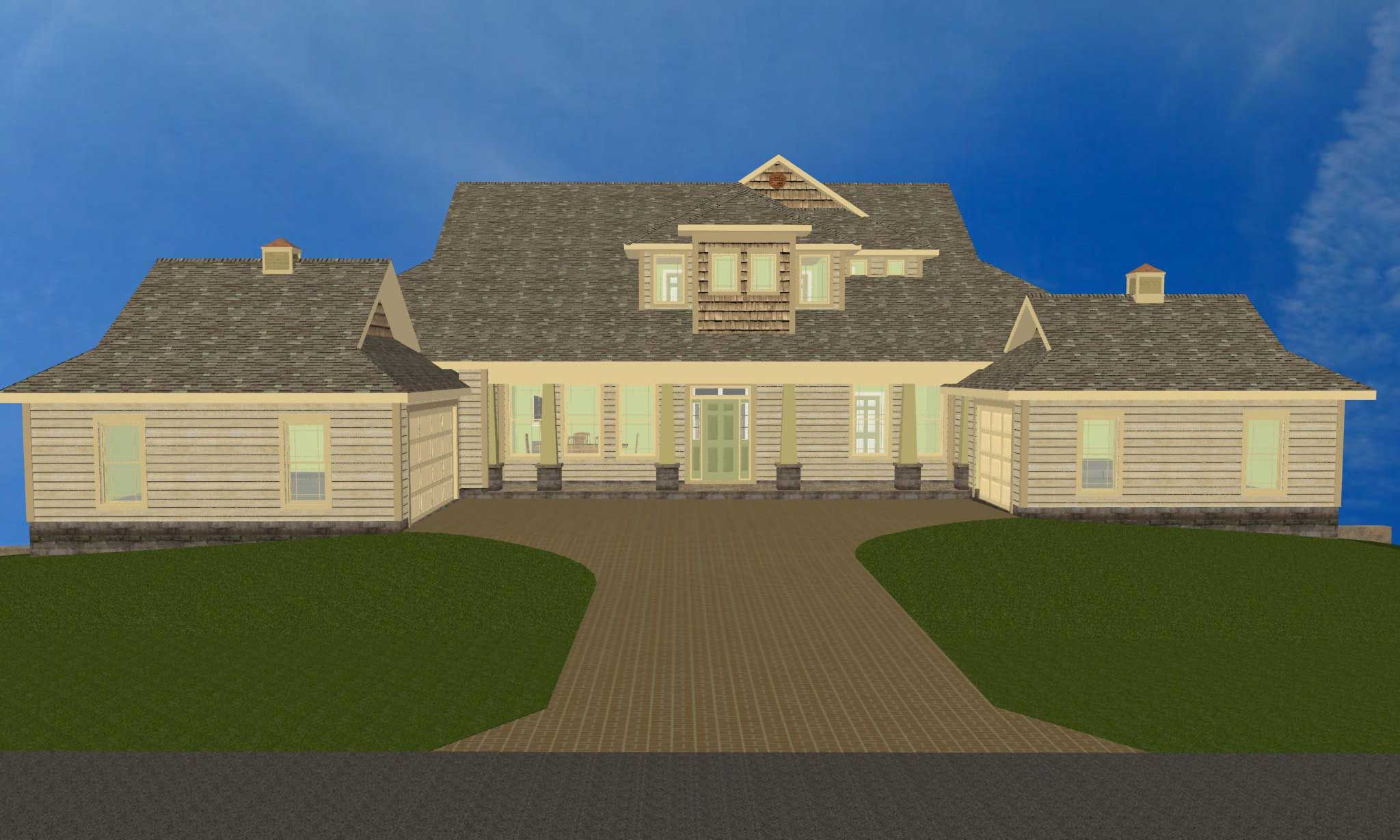

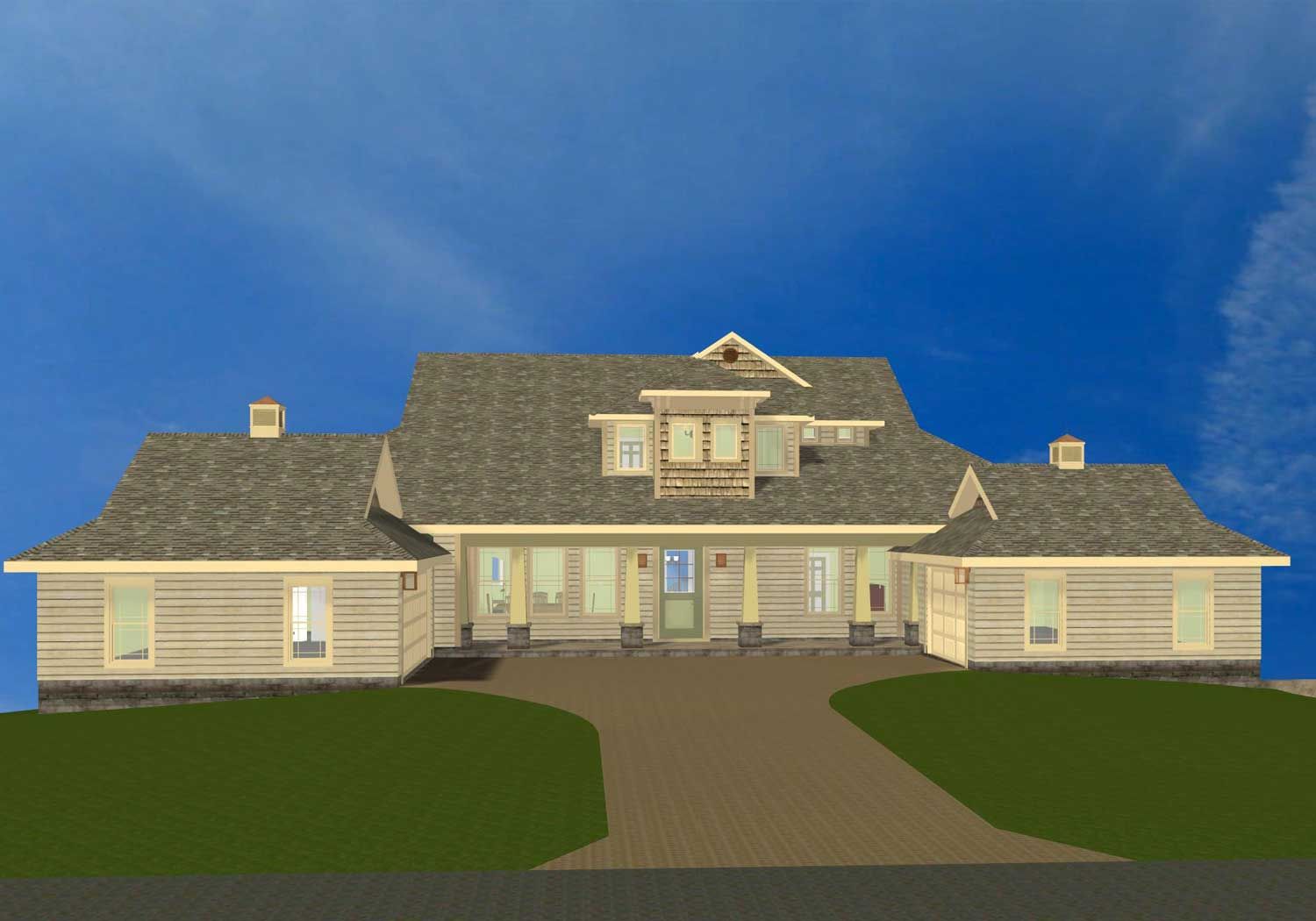

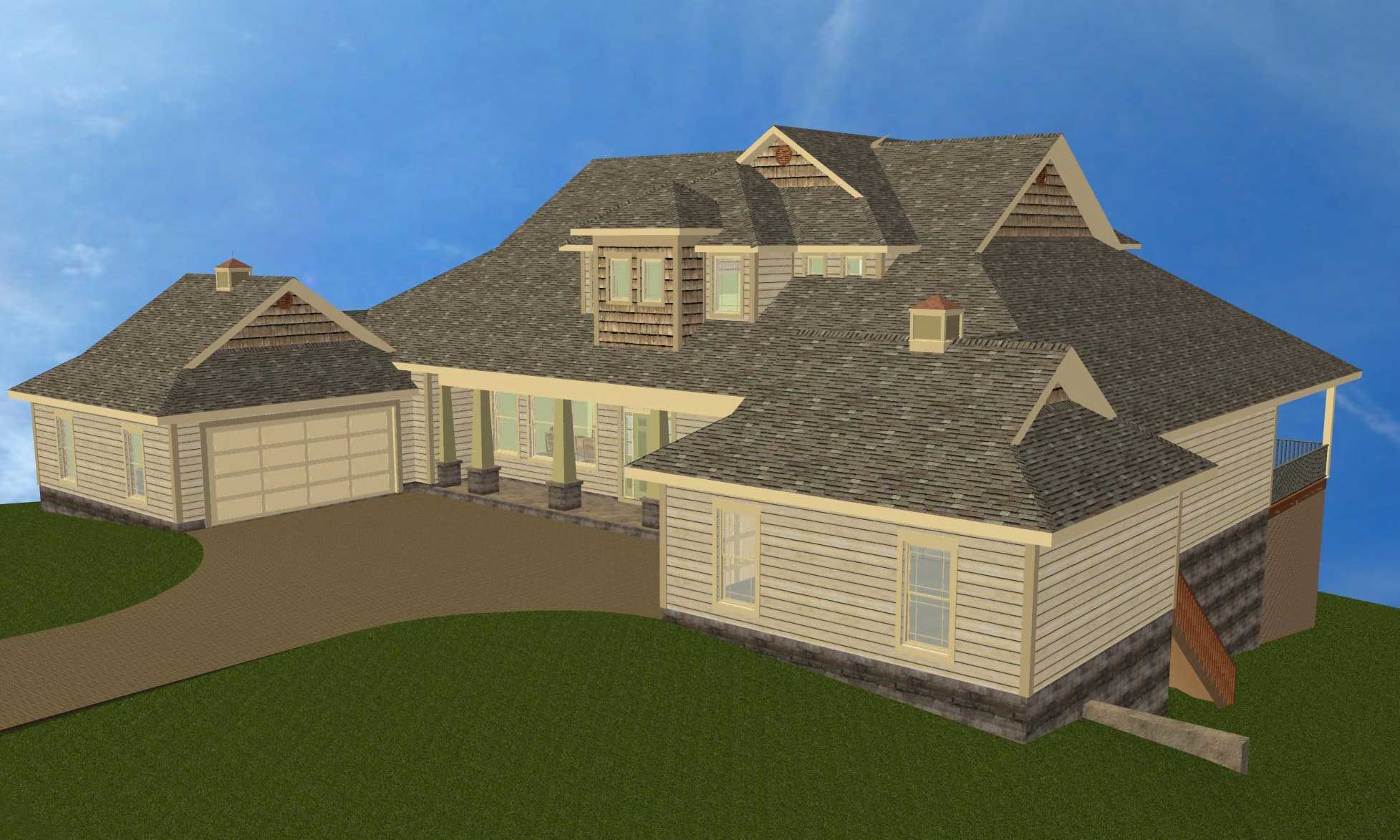

Carter residence

The Carter home includes all the latest "aging in place" features designed to allow Tom & Pauline to enjoy living in their home for the rest of their lives, close to family, friends, and convenient to shopping. We built high on a blugg to take advantage of a spectacular view of Escambia bay. This is the 3rd project I have done for Tom Carter. It should be the last one because I don't know how I'm going to top it.